Acrylate

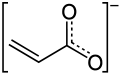

Acrylates (IUPAC: prop-2-enoates) are the salts, esters, and conjugate bases of acrylic acid. The acrylate ion is the anion CH2=CHCO−2. Often, acrylate refers to esters of acrylic acid, the most common member being methyl acrylate. These acrylates contain vinyl groups. These compounds are of interest because they are bifunctional: the vinyl group is susceptible to polymerization and the carboxylate group carries myriad functionalities.[1]

Monomers[edit]

Acrylates are defined by the formula CH2=CHCO2R, where R can be many groups:

- Acrylic acid

- Methyl acrylate

- Ethyl acrylate

- 2-Chloroethyl vinyl ether

- 2-Ethylhexyl acrylate

- Butyl acrylate

- Trimethylolpropane triacrylate (TMPTA)

The versatility of the resulting polymers is owed to the range of R groups.

- Structures of some acrylates

-

The acrylate anion

-

Trimethylolpropane triacrylate (TMPTA), a trifunctional acrylate ester

-

Methyl acrylate, an acrylic ester

-

Hexandiol diacrylate, a bifunctional acrylate

-

Pentaerythritol tetraacrylate (PETA), a tetrafunctional acrylate

-

A generic polyacrylate

Acrylate derivatives[edit]

Methacrylates ( CH2=C(CH3)CO2R) and cyanoacrylates ( CH2=C(CN)CO2R,) are closely related to acrylates. The feature a methyl and a nitrile in place of the H alpha to the carboxy functional group. They share several properties, being polymerized by radicals and being colorless.[2]

- Structures of some important modified acrylates

-

Methyl methacrylate, precursor to "perspex" (plexiglass)

-

Ethyl cyanoacrylate, precursor to "super glue"

Polymers[edit]

Some acrylate polymers (poly(methyl methacrylate) etc. not included):

Acrylate monomers are used to form acrylate polymers. Most commonly, these polymers are in fact copolymers, being derived from two monomers.[3][4]

Related polymers[edit]

In the same way that several variants of acrylic esters are known, so too are the corresponding polymers. Their properties strongly depends on the substituent.

A large family of acrylate-like polymers are derived from methyl methacrylate and many related esters, especially polymethyl methacrylate.

A second large family of acrylate-like polymers are derived from ethyl cyanoacrylate, which gives rise to cyanoacrylates.

Yet another family of acrylate-related polymers are the polyacrylamides, especially the parent derived from acrylamide.

Other uses[edit]

In addition to forming polymers, acrylate esters participate in other reactions relevant to organic chemistry. They are Michael acceptors and dienophiles. They undergo transesterification.

Production[edit]

Acrylates are industrially prepared by treating acrylic acid with the corresponding alcohol in presence of a catalyst. The reaction with lower alcohols (methanol, ethanol) takes place at 100–120 °C with acidic heterogeneous catalysts (cation exchanger). The reaction of higher alcohols (n-butanol, 2-ethylhexanol) is catalysed with sulfuric acid in homogeneous phase. Acrylates of even higher alcohols are obtainable by transesterification of lower esters catalysed by titanium alcoholates or organic tin compounds (e.g. dibutyltin dilaurate).[5]

See also[edit]

- Acrylate polymer

- Sodium polyacrylate thickeners

- Methacrylate

References[edit]

- ^ Takashi Ohara; Takahisa Sato; Noboru Shimizu; Günter Prescher; Helmut Schwind; Otto Weiberg; Klaus Marten; Helmut Greim (2003). "Acrylic Acid and Derivatives". Ullmann's Encyclopedia of Industrial Chemistry. Weinheim: Wiley-VCH. doi:10.1002/14356007.a01_161.pub2. ISBN 3527306730.

- ^ Veerle Coessens; Tomislav Pintauer; Krzysztof Matyjaszewski (2001). Functional polymers by atom transfer radical polymerization. Vol. 26. pp. 337–377. doi:10.1016/S0079-6700(01)00003-X.

{{cite encyclopedia}}:|journal=ignored (help) - ^ Takashi Ohara; Takahisa Sato; Noboru Shimizu; et al. (2002). "Acrylic Acid and Derivatives". Ullmann's Encyclopedia of Industrial Chemistry. Weinheim: Wiley-VCH. doi:10.1002/14356007.a01_161.pub2. ISBN 978-3-527-30673-2.(subscription required)

- ^ "Polyacrylates".

- ^ Arpe, Hans-Jürgen (2007). Industrielle organische Chemie: bedeutende Vor- und Zwischenprodukte (6 ed.). Weinheim: Wiley-VCH. ISBN 978-3-527-31540-6.